Spray Rinse Valve

Fetterolf rotating Spray Rinse Valves (also referred to as wash down valves) are designed to effectively rinse any size tank, vessel or reactor without the need to open them. This increases production time but more importantly assures employee safety by eliminating the requirement for personnel to enter a vessel or confined space that potentially has hazardous or toxic material.

Spray Rinse Valve - Rotating design

Spray Rinse Valve - Rotating design Spray Rinse Valve

The Fetterolf rotating Ram-Seal spray rinse valve is used to clean the vessel walls of loosely attached coatings and solids to prevent build up and batch to batch contamination. This is extremely important in services that contain harmful substances that are life threatening such as VCM.

The rotating or linear washdown valve (spray rinse valve) is mounted to the top of the vessel. The number and size of valves are determined by the process, size and shape of the vessel. The valve eliminates the need for vessel opening or closing.

- Rotating and linear spray rinse valve designs

- 360 degree cleaning

- Simple installation

- Ease of maintenance

- Custom sizing for your vessel/pump

- Wide range of materials.

- Customised spray patterns upon request

- Ram-Seal sealing mechanism

The spray rinse valve starts in the closed position, the wash fluid pump is turned on and pressure is built up inside the

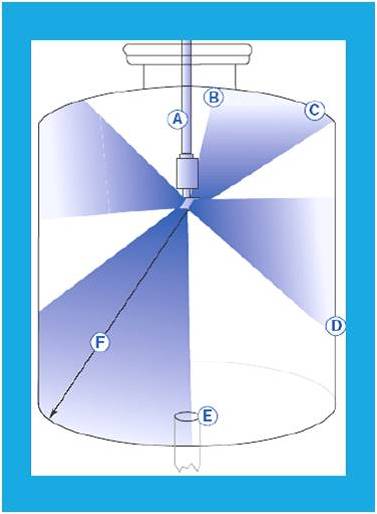

valve. The SR valve actuator is given the open signal and the valve begins to open. As the valve opens wash fluid is directed straight down and blasts the inside of vessel cleaning the drain valve.

The valve continues to open and the wash fluid fans out upwardly on the vessel walls. The valve reaches full stroke and automatically goes into rotation to wash 360 degrees of the vessel wall. The actuator is given the close signal and the valve stops rotating and goes to the fully closed position and stops. The wash fluid pump at this time is stopped. Please press the video tab above to see the effectiveness of the Fetterolf Spray Rinse Valve in live action.

- Materials of Construction –

- 300 series stainless steels,

- nickel and nickel alloys,

- titanium,

- duplex, super duplex and many more on request.

- Actuation – Manual, electric and air motor.

- Limit switches and air control valves.

- Decreased batch times

- Increased productivity

- Improved product quality

- Reduced emissions

Spray Rinse Pattern

The Fetterolf spray rinse valve has been designed to allow cleaning of a vessel or reactor without entering the vessel or reactor. It is the result of many years of research and optimisation in live customer applications. Its most common application

is in the PVC industry. It is also used in styrene reactors and other polymer and paint applications. A high degree of customisation of the spray tube is available to ensure optimal rinsing for reactors that may have diverse pieces of equipment in the reactor (UV tubes in the CPVC process for example).

One key advantage of the Ram-Seal spray rinse valve design is that no chlorine, other gases or sediments can enter the valve in the open or closed position. This ensures free flowand no clogging, and means that the valve is always available to clean. It also ensures that any toxic gases in the reactor stay in the reactor.