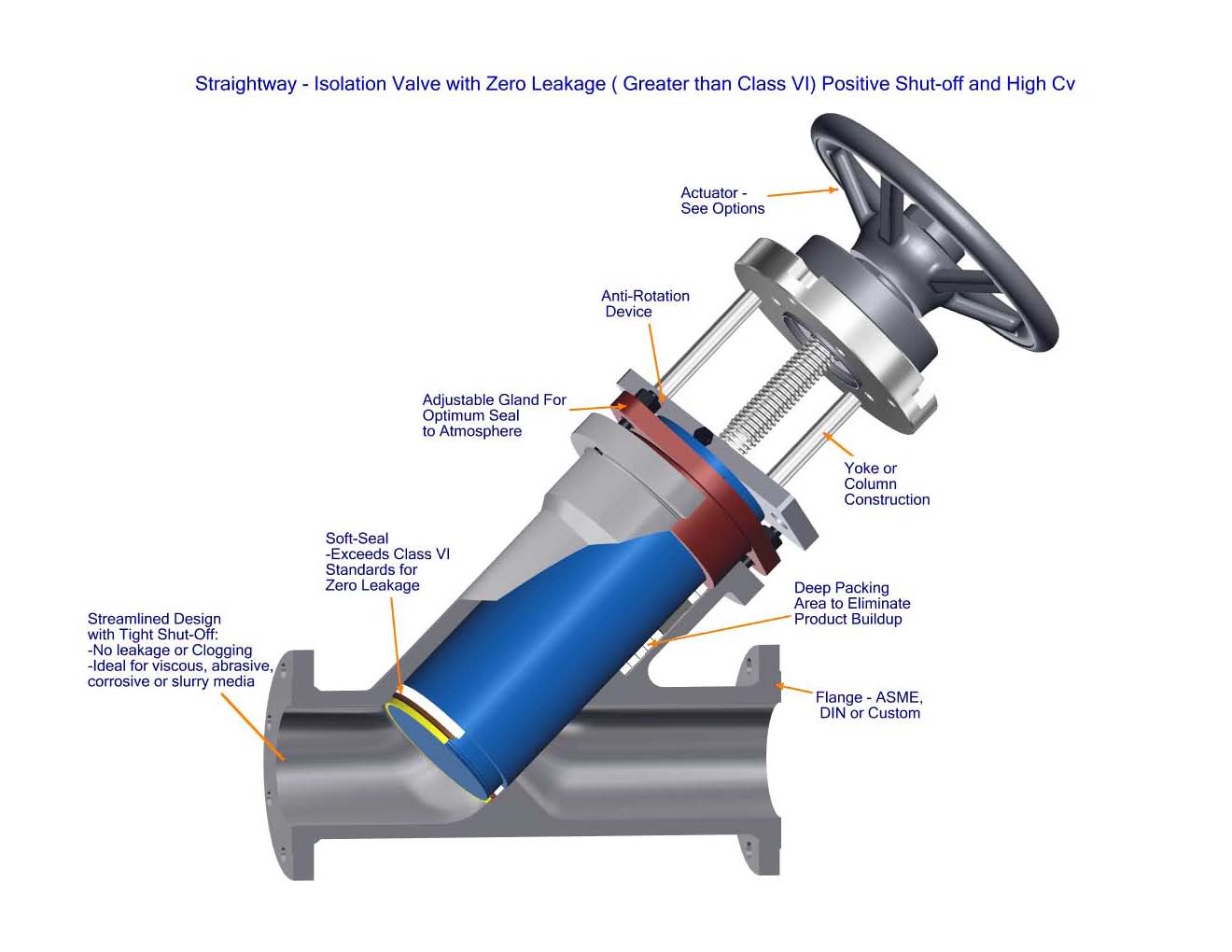

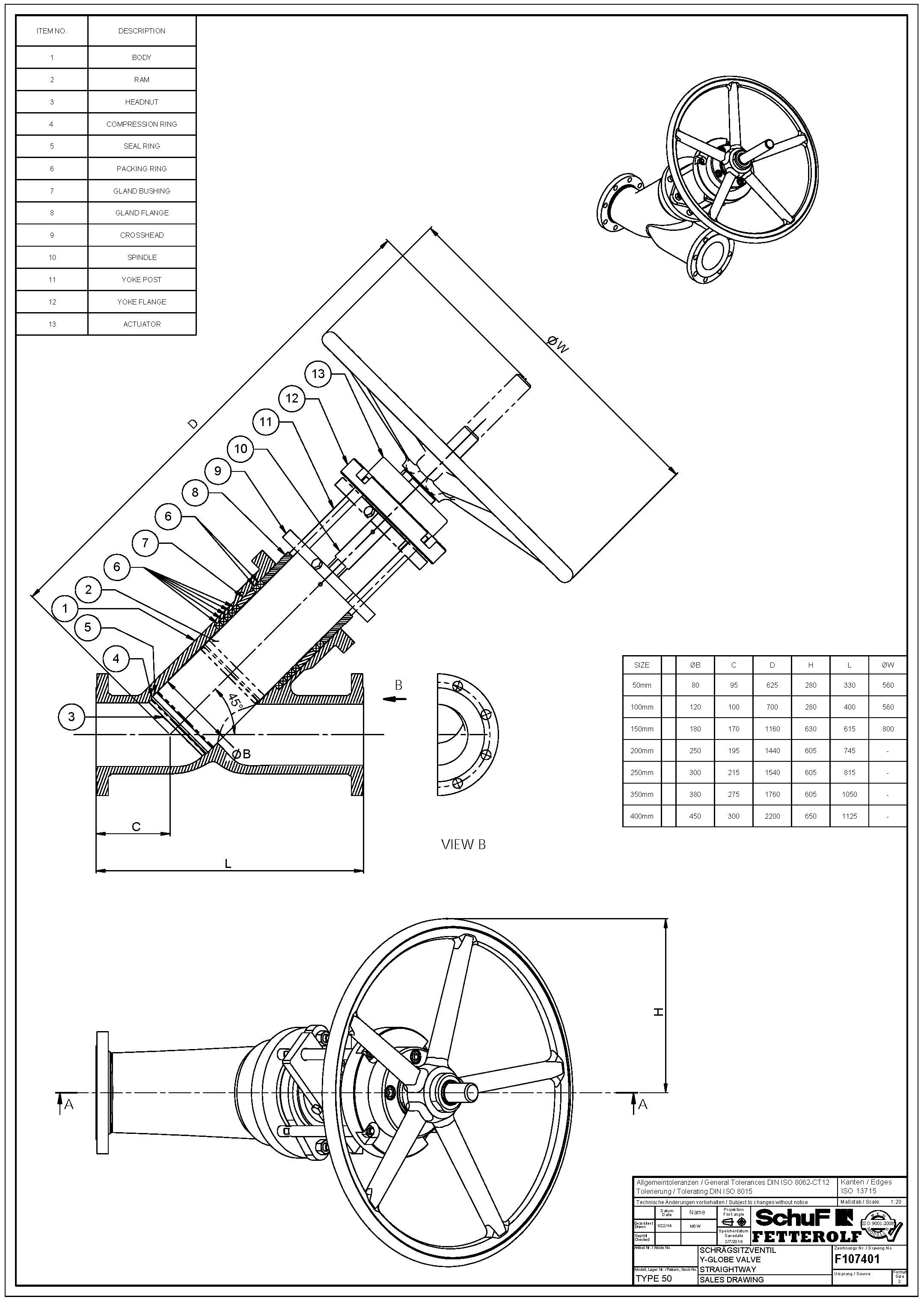

Straightway Globe Valve

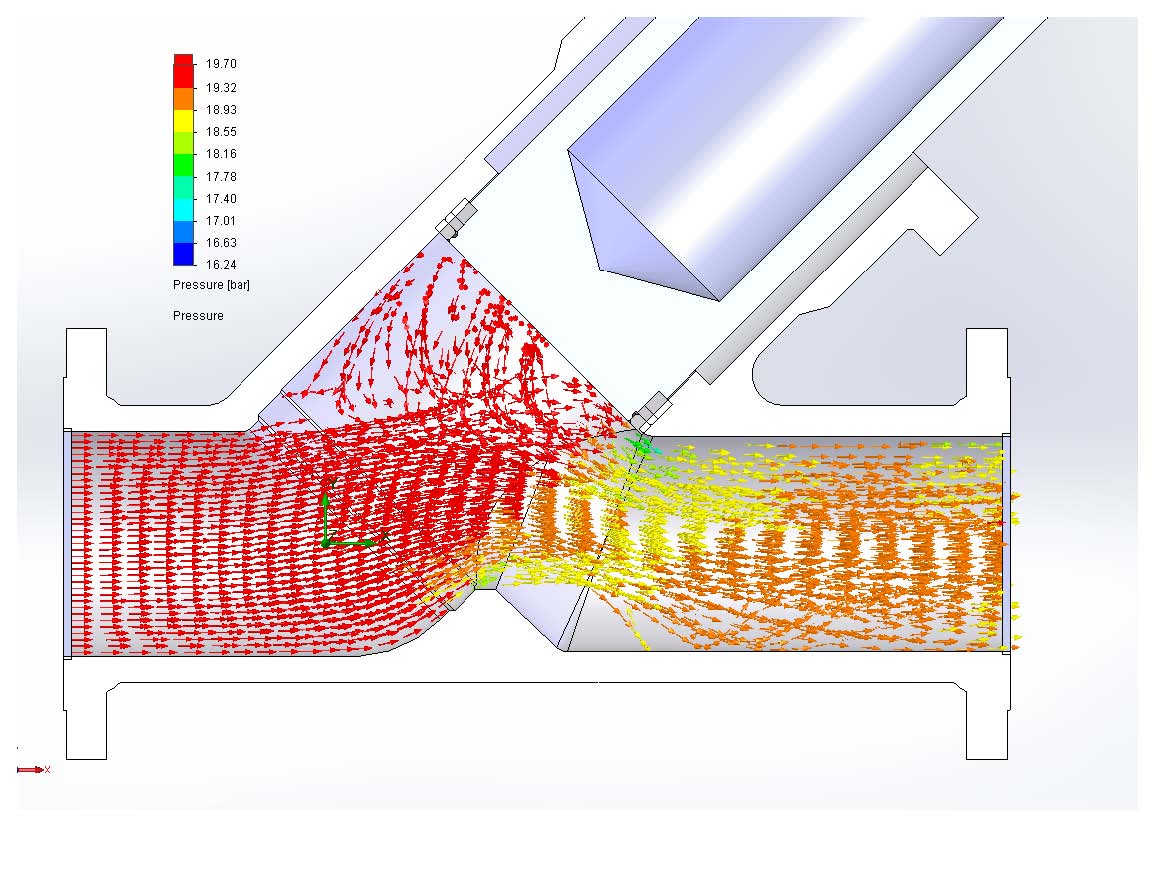

The Fetterolf Straightway Y-Globe valve is an in-line isolation valve that is designed to deliver a high Cv and low pressure drop. This is achieved by its streamlined body design and unobstructed flow. This also enables the valve to be roddable.

It's Ram-Seal sealing mechanism assures positive shut-off. The combination of these characteristics make it the in-line isolation valve of choice for severe service.

Ideal for Severe Operating Conditions

The Fetterolf Straightway Valve has become a standard, in-line, or "WYE" pattern valves in severe applications.Certain applications require tight shut-off, under high pressure or high flow capacity (Cv) and free draining with over sized ports without "pockets" , or low points where material can collect. Some applications require all three.

The Fetterolf Straightway valve excels in these applications and where high pressure polymer, ultra pure, or erosive media are encountered.

Application

The Straightway Y-Globe valve has been installed in many plants and processes in the Chemical, Petrochemical and Refining industries. As a standard Y-Globe it delivers non leak Class VI sealing characteristics.

It is also the valve of choice in processes that have highly viscous, erosive or high slurry content media due to its optimized body flow design, that ensures a high Cv, low Delta P and a roddable functionality. Such features are commonly found in the Mineral Processing, Polymer and Heavy Oil Upgrading industries.

The Straightway in-line isolation valve or Y-Globe valve has many benefits and features:

- Ram-Seal design assures no leakage or clogging

- Tight shut-off, exceeds requirements of class VI standards for zero leakage

- Oversized ports

- No low spots for material to collect

- High Cv values (Please see Dimension and Cv Tables)

- Ideal for viscous, abrasive, corrosive erosive or slurry like media

- Available from 1” (DN25) to 24” (DN600) and up to ASME 2500# as standard

- Minimal pressure drop (Delta P)

- Jacketed designs

The Straightway valve comes with many options to improve performance or meet specific application requirements. It exceeds most standard Y-globe valves or in-line isolation valves:

- Full body jacketing

- Bellows stem seal

- Flanged, butt weld, socket weld and threaded end connections

- Manual, pneumatic, hydraulic or electric actuation

- Limit switches

- Position indicators

- Control systems

- Lantern ring packing

- Flushing connections

- Materials - All stainless steel grades, Alloy 20, Inconel, Titanium, Nickel, Hastelloy, Carbon steel and Monel

The optimised Straightway valve design allows a High Cv without sacrificing its Class VI seal to process.

The Ram-Seal Principle

The Ram-Seal® valve works by having a plunger (Ram) operating within a cylinder. When the valve is closed the plunger (Ram) occupies the entire inner bore in the valve body leaving minimal space for particles to collect.

The primary sealing is provided by a resilient seal ring mounted on the Ram. It travels with the Ram throughout the stroke. It seals when the seal ring receives a thrust force from a compression ring as the Ram moves to the closed position. The seal ring is expanded into a wide band seal against the surface of the sealing barrel (Seat) and against the Ram.

In the open position the seal ring is retracted out of the flow stream hereby being protected from abusive forces from flow and velocity. The wear on the seal ring is minimized as the sealing contact occurs only while the Ram travels the short distance of the seating area.