A core value at Fetterolf is innovative design. Innovation is the ability to see what is possible even if it does not seem possible at first sight.

Many of our “standard” valves already operate at the highest levels. The Ram-Seal tank/drain valve for example delivers drop tight shut-off (1 x 10-8 cc/sec) and superior seal to atmosphere as a standard. But our approach is to partner with end clients to see what might be possible, to improve valve design that meet their application needs. This can take many forms, but it inevitable leads to innovative and flexible design.

Flexible Design

Flexible design – each and every Fetterolf valve is designed specifically for a customer installation. We can design a valve with customized face to face dimensions, varying branch angle orientations, or unique bore or inlet/outlet sizing, different end connects or special trim.

This flexible design approach approach is reinforced by our “For Approval” (FA) drawings followed by “Final and Certified” (FC) design process and often leads to valve innovation.

We produce a drawing of the valve that we believe that our customer requires (FA) but allow them to review and suggest changes. Once agreed a final drawing is produced.

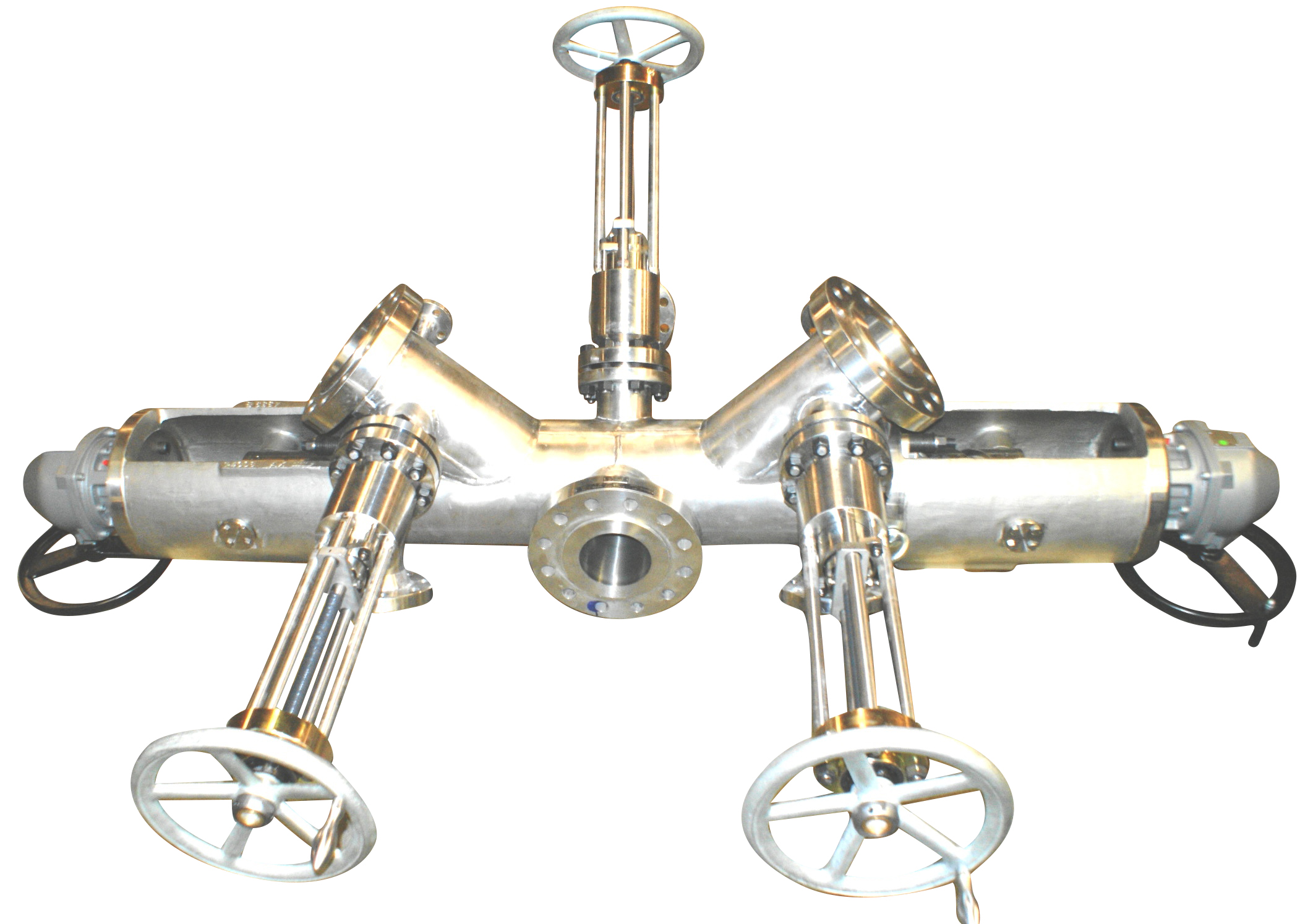

For a major oil company we designed a series of compact diverter valves for a new refinery that needed to optimize the space to be used as well as reducing back flushing. The result can be seen on the left. The flexible design process allowed us to create not only a valve that reduced plant foot space by 40%, but also a valve with increased performance and flow characteristics - true innovation.

For a major Petrochemical producer of HDPE we have proposed a series of designs for a loop reactor drain valve over a long number of years leading to an exceptional mean time between maintenance (MTBM) value of 5-6 years. This was a result of a combination of using new materials and an improved sealing mechanism.

Application Specific Valve Innovation

But this is only the start. Upon request we design Application Specific Valves or customized valves. These designs focus on specific requirements such as reduced pressure loss, better flow characteristic, elimination of dead space, or a combination of severe operating conditions to which the valve must perform. These customised valves often lead to material, or flow characteristic innovation. For a major supplier of Aramid (Spandex) we provided a diverter valve to switch between two filters.

The customer requested a low pressure drop so that the medium would not be disrupted when switched from one filter to another. Using CFD analysis and by introducing several new design features we were able to reduce the pressure loss to such an extent that the filters did not even notice that the diverter valve had been put in place. This development has led to a true innovation and a category of valves for sensitive filter transfer applications referred to as “Bumpless transfer valves”. These new flexible designs and innovative features are important in many applications including the production of Kevlar, Lycra and other fine strand polymers.

Turnkey Innovation

For the PVC industry we offer Turnkey solutions for the critical reactor part of the plant. We have partnered with plant and process engineers of end users for over 40 years to better understand their whole flow process, and what they need to achieve. The result is a series of valves optimized for PVC production that includes spray rinse valves with customized spray patterns for different PCV processes, a unique “seatless” drain valve - Rod-Seal Valve - that eliminates dead space, and reduces maintenance.

Yet other valves are used for VCM feed, water feed, reflux condenser rinsing, and line isolation valves. Thanks to the joint collaboration with the PVC industry many new innovative features have been introduced over the years leading to greater reliability and improved efficiency. These are just some of the examples where our flexible design process, application specific focus and turnkey innovation that enable Fetterolf to provide customized valves that outperform expectations.